Our environmental interventions in Ravenna

From a historic petrochemical hub to a concrete example of circularity thanks to a project that gives new life to reclaimed areas.

Ravenna, from remediation to productive redevelopment

Ravenna at a glance

Ravenna past and present

Site history.

Eni Rewind becomes owner of the disused areas

Polimeri Europa (Versalis) acquired the production of styrenics, elastomers, olefins and intermediates from Enichem and Eni Rewind became the owner of all the disused internal and external areas.

Enipower enters the plant

The power plants and related services are sold to Enipower.

Remediation interventions begin

Enichem begun the first environmental interventions in Ravenna.

The industrial scenario at the plant begins to change

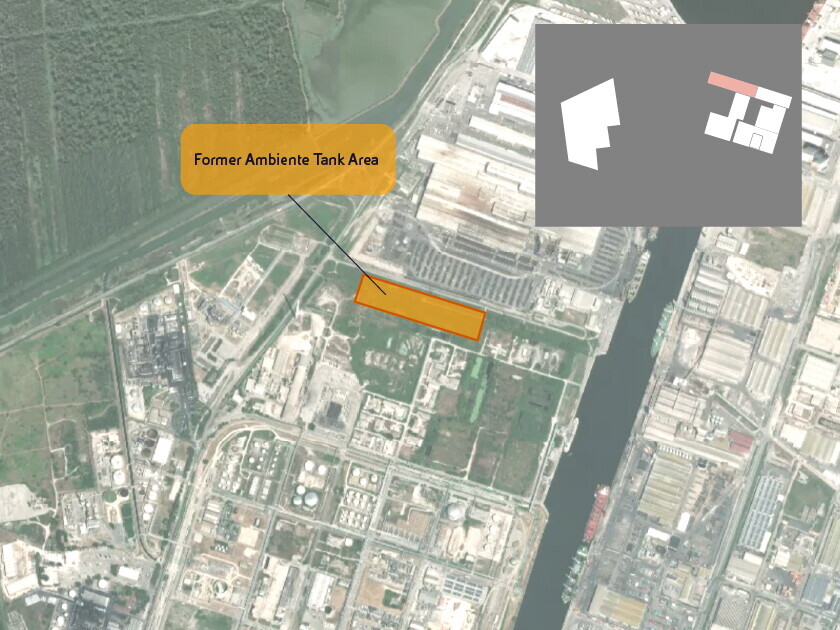

The Agricoltura business unit is transferred to Hydro Agri Italia, vinyl acetate to Vinavil, diphenols to Borregaard, later CVM/PVC to EVC, while TAS and the cement plant are transferred to Ambiente.

The trasfer to Enichem

The activities passed from Anic to Enichem.

Production expansion

The production of PVC, acetates and fine chemicals (DMC) was added in the 1960s.

The Ravenna petrochemical complex is established

The origin of the Ravenna complex dates back to 1954 when Enrico Mattei entrusted ANIC with the construction of the first synthetic rubber factory in Italy.

Our activities in Ravenna

Ravenna’s complex

Status of the environmental process

The administrative procedures for environmental interventions in the areas owned by Eni Rewind are all completed and obtained the relevant municipal certification.

Project approved

Project approved

Project approved and certified

Project approved and certified

Project approved and certified

Project approved and certified

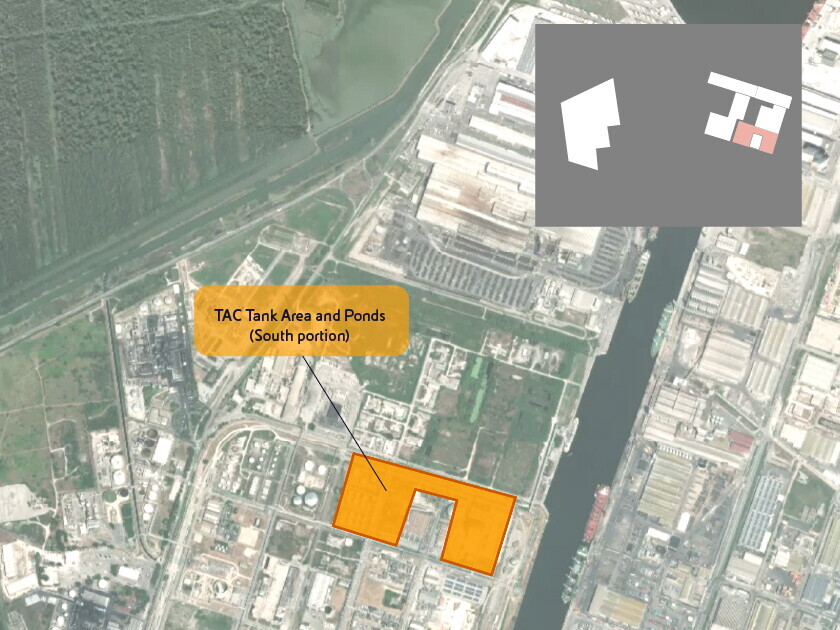

Operative remediation project approved by the Municipality of Ravenna in 1999.

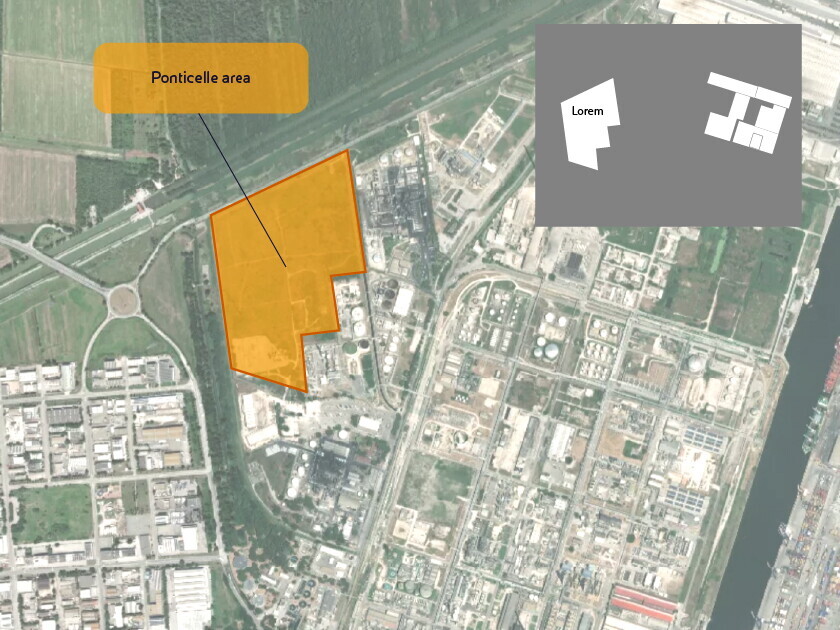

Variant to the Operative remediation project for sediment and soil in the Ponticelle area, Phase II – 1st excerpt – Disposal of above-ground deposits approved by the Municipality of Ravenna in 2015.

Variant to the Operative Remediation Project for sediment and soil in the Ponticelle area, Phase II – 2nd excerpt – permanent safety measure intervention approved by the Municipality of Ravenna in 2018.

Certification of completion of the permanent safety measure interventions issued in 2021 by ARPA Emilia-Romagna.

Project approved

Ponticelle: recovery and redevelopment of a former industrial area

The Ponticelle project, a disused industrial area outside the Ravenna petrochemical plant, is a concrete example of how remediation can bring added value to land and the local communities. We are implementing a virtuous development model for the regeneration of production, in line with the circular economy principles. As the owner company of the former industrial area, we first finalised permanent safety measures with capping that covered 18 of the 26 hectares of the total surface and then began the interventions for its valorisation. Overall, the project foresees a bio-recovery platform, a multifunctional waste pre-treatment platform (realised by HEA, a company consisting of a joint venture between Eni Rewind and Herambiente Servizi Industriali) and a photovoltaic plant completed by Plenitude in February 2024. Urbanisation works and services in the area are also undergoing completion.

Starting from the first quarter of 2026, in the Ponticelle area will be in operation:

- The Eni Rewind soil biorecovery platform With a treatment capacity of 80,000 tonnes per year, is dedicated to the aerobic biodegradation of hydrocarbon- contaminated soils; using indigenous microorganisms (fungi and bacteria), primarily originating from the remediation of service stations. The aim is to recover treated and recovered soil (end of waste) for reuse to fill up excavations in service stations undergoing reclamation activities, reducing landfill disposal and the use of virgin resources. The platform, which will cover 3 hectares, also includes a bio-laboratory for conducting analytical checks on the conformity of the waste entering the plant and periodic monitoring surveys of bioremediation, as well as on the post-treatment materials (end of waste) for reuse.

- The HEA multifunctional platform for the management of industrial waste With Herambiente, through the establishment of the joint venture HEA, we are developing a cutting-edge platform for the pretreatment of industrial waste. This significant synergy nables to reach self-sufficiency at regional level, optimising waste recovery and valorisation, also as secondary materials, promoting the recovery of energy and materials from the industrial waste collected. The plant, which will replace the current HASI (Herambiente Servizi Industriali) platform, will manage up to 60,000 tonnes per year of special waste from environmental and industrial activities, in particular local ones, in line with the European directives of the Circular Economy Package.

- The Plenitude photovoltaic plant With an installed capacity of 6 MW, Plenitude’s plant, completed in February 2024, covers an area of 11 hectares and is made up of over 10,000 photovoltaic panels mounted on special structures equipped with a solar tracking system, which are fixed on ballasts placed over the waterproof capping of the permanent safety measures interventions. Once fully operational, the photovoltaic plant will produce the energy equivalent to the needs of over 3,000 families.